Cotton vs Viscose Rayon

In this article, we’re going to take a look at the differences between cotton and viscose rayon.

While both cotton and rayon fibers are made from cellulose, the cellulose used for cotton comes from plants and takes five or six months to grow, but rayon’s cellulose comes from trees and takes much longer – sometimes even years – to mature enough for harvesting.

These trees are processed chemically in order to separate the cellulose from the bark, lingin, etc., which is then regenerated into man-made fiber.

Because the molecules in cotton have longer cellulose chains than the molecules in rayon, these longer cotton molecules also packed line up with each other more than rayon’s shorter ones do.

For these reasons, the fibres of cotton are much stronger than those of

rayon.

The Unique Properties of Cotton

These same molecular properties mentioned above also contribute to the fact cotton fibers actually increase in strength when they become wet.

The fibers of viscose rayon, on the other hand, become weaker when they get wet.

An increase in strength when wet becomes important in the case of wipes used for absorbing spills, as well as for pre-moistened wet wipes.

This increase in strength when wet is also beneficial in the case of medical products used for cleaning, protecting, or absorbing bodily fluids, and even for supporting bodily organs during surgery.

Regenerated Fibers Are Not Technically Natural

Cotton fibers are produced from plants and there are a variety of seeds used for growing it.

The kind of cotton seed which is used is determined primarily based on the conditions in the region in which it is planted (a wet or dry, short or long growing season, for example).

Viscose rayon is produced from a number of different trees, grasses or in some cases even cotton, since in each case the key ingredient is cellulose. Certain rayon fibers are made from bamboo (a type of grass) as the source of the cellulose.

Lately certain false claims have been made in order to label rayon fiber made from regenerated bamboo plants as “natural” — it was implied to consumers that these were natural fibers produced directly from bamboo—but “regenerated” is the operative word in this case.

Grown & Processed Locally

Another advantage to cotton is that it is grown in the U.S. throughout the southern states, all the way from Virginia to California.

By contrast there are no producers of viscose rayon whatsoever in all of North America. Moreover in the case of cotton, for every pound of fiber that is harvested there are approximately 1.6 pounds of other products created, for example cottonseed oil, mulch, or cattle feed.

As a matter of fact, in the past 20 years modern techniques for farming cotton have lowered the energy needed for cotton production by 66%. Moreover, over the course of those two decades water used in cotton production has gone down by 49%, carbon dioxide emissions by 33%, and soil loss by 34%.

At the same time new varieties of seeds have reduced the use of pesticides by 23%.

These cotton farming techniques mean that less is more make cotton the superior choice in terms of sustainability and the environment.

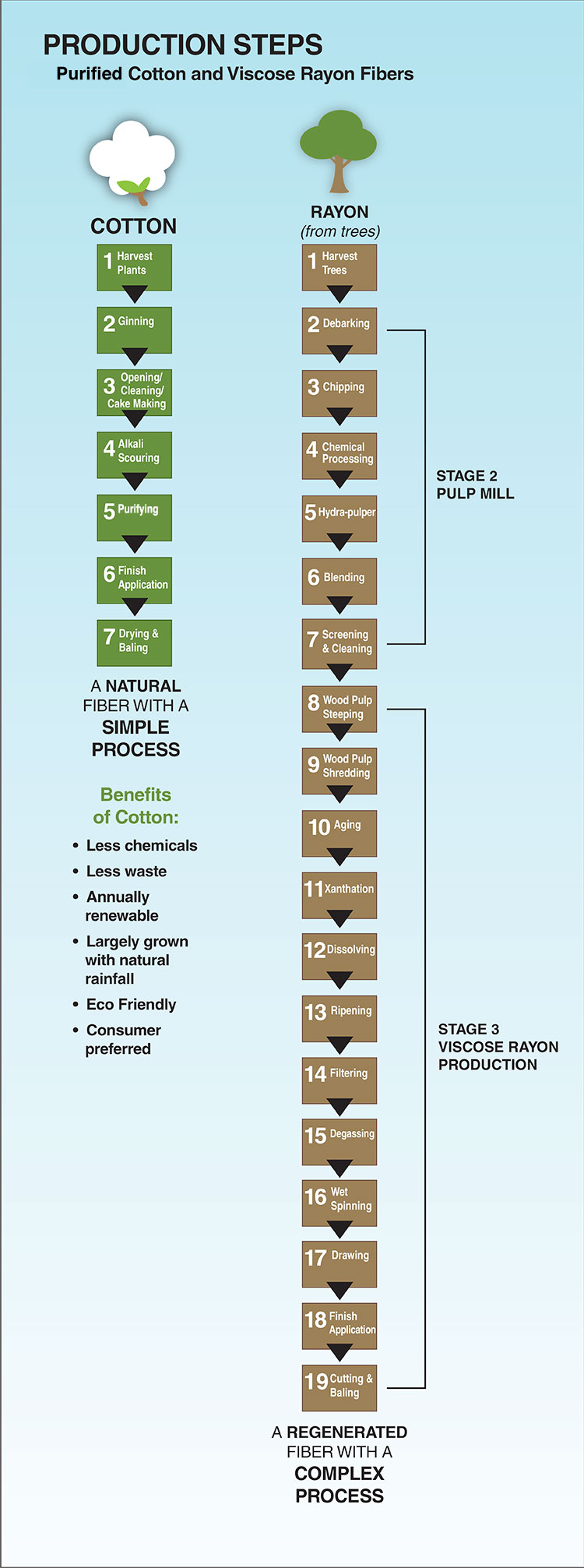

Production Steps in Purified Cotton vs Viscose Rayon

Let’s have a look at the processes for producing both purified cotton and viscose rayon.

Viscose rayon can be produced from many different sources of cellulose, but because the majority produced commercially comes from trees, we’ll take look at that production process.

As you will see in the diagram below, the process for producing cotton fibers is far simpler.